IndiaQo Foods Pvt Ltd supplies premium frozen sweet corn And diced vegetables year-round to retail, food service, and industrial clients. We prioritize exceptional quality and guaranteed food safety, sourcing the finest produce from top growers.

Raising the Bar with Trusted Certifications to Nurture Strong Customer Relationships

Farmers cultivate and grow a variety of vegetables in their fields. These vegetables are carefully tended to, ensuring they receive the right amount of water, nutrients, and sunlight Harvesting is done at the peak of freshness to capture maximum flavor and nutritional value.

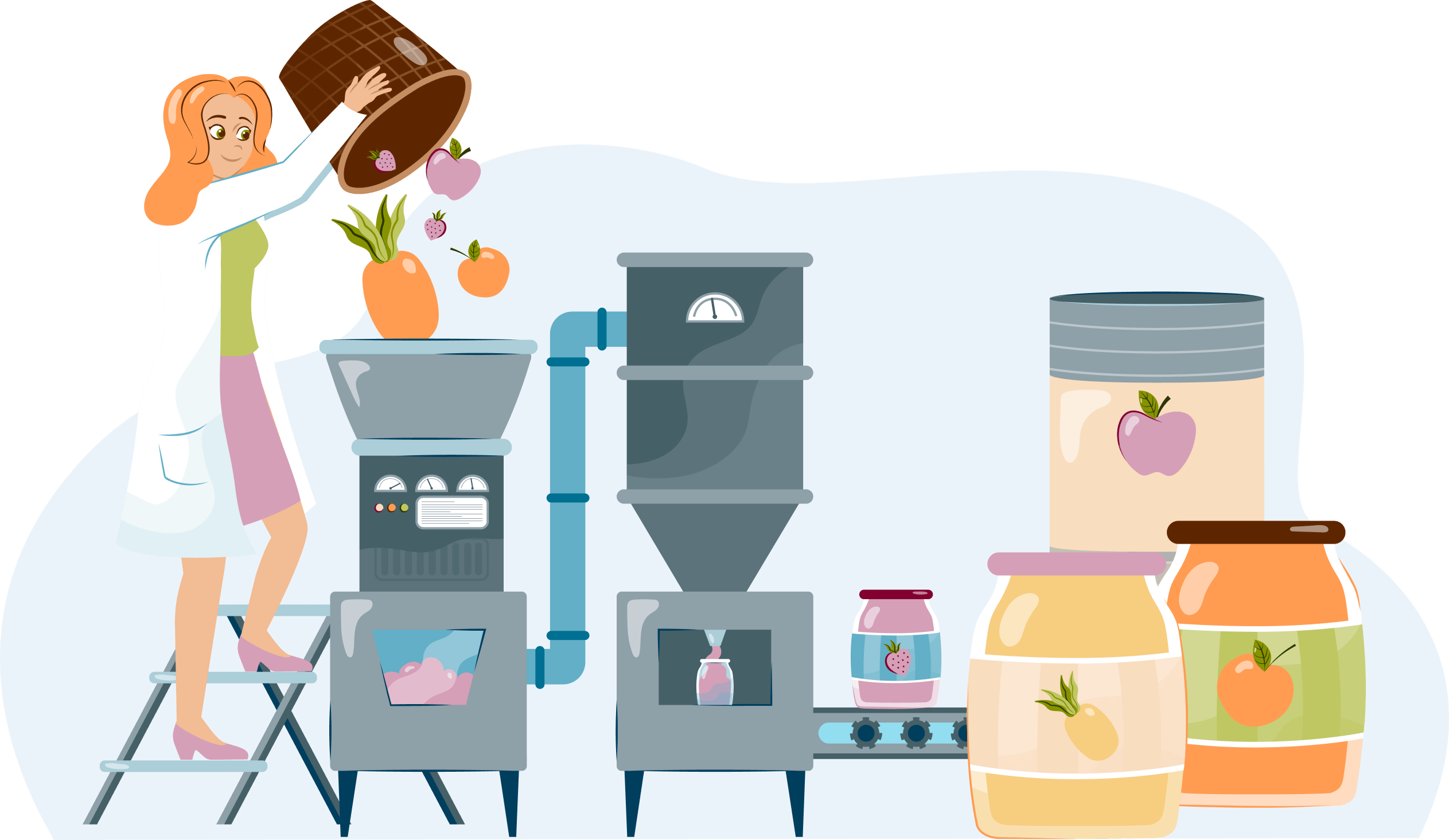

This may involve washing, peeling, and cutting them into the desired size and shape. The goal is to maintain the quality and integrity of the vegetables. Blanching is a crucial step in the frozen food process. Vegetables are briefly blanched in hot water or steam. This helps to deactivate enzymes that can cause deterioration in color, flavor, and nutritional content.

After blanching, the vegetables are rapidly frozen. Quick freezing helps to preserve the texture, color, and nutritional value of the vegetables. It prevents the formation of large ice crystals that could damage cell structure.

Frozen vegetables are then packaged in a way that minimizes exposure to air and moisture, which can lead to freezer burn. Packaging materials are chosen to maintain the quality of the vegetables and prevent contamination.

Frozen vegetables are stored in cold storage facilities to maintain their frozen state until they are ready for distribution. Distribution networks ensure that the frozen vegetables reach various retailers and markets.

We strive to achieve excellence in complex logistical operations through multiple in-house and 3p distribution centres based out in major cities across the country. Our high-tech, GPS-enabled systems of refrigerated & dry fleets support synergized actions and meet on-time delivery commitments along with maintaining utmost quality controls.

Farmers cultivate and grow a variety of vegetables in their fields. These vegetables are carefully tended to, ensuring they receive the right amount of water, nutrients, and sunlight. Harvesting is done at the peak of freshness to capture maximum flavor and nutritional value.

This may involve washing, peeling, and cutting them into the desired size and shape. The goal is to maintain the quality and integrity of vegetables. Blanching is a crucial step in the frozen food process. Vegetables are briefly blanched in hot water or steam. This helps to deactivate enzymes that can cause deterioration in color, flavor, and nutritional content.

After blanching, vegetables are rapidly frozen. Quick freezing helps to preserve the texture, color, and nutritional value of vegetables. It prevents the formation of large ice crystals that could damage cell structure.

Frozen vegetables are then packaged in a way that minimizes exposure to air and moisture, which can lead to freezer burn. Packaging materials are chosen to maintain the quality of vegetables and prevent contamination.

Frozen vegetables are stored in cold storage facilities to maintain their frozen state until they are ready for distribution. Distribution networks ensure that the frozen vegetables reach various retailers and markets.

We strive to achieve excellence in complex logistical operations through multiple in-house and 3p distribution centres based out in major cities across the country. Our high-tech, GPS-enabled systems of refrigerated & dry fleets support synergized actions and meet on-time delivery commitments along with maintaining utmost quality controls.

Verify our official listing on Trade Connect Portal

We extend out heartiest congratulations for the setup up of one of the finest Food Processing units that we have visited in India. We are amazed to see the factory and realise how well everything has been planned to minute details. The factory Layout has been perfect, right from the entrance to manufacturing area, the well laid Concrete roads, thoughtfully planted trees and the treated water being used for gardening. Main Processing plant is well planned with multiple activities which is adorned with clear and extensive signages. It was amazing to see the excellent working of machines, the quality output of the JBT IQF machine and the hygiene were in line with BRC standards. The frozen cold storage chambers were very elegantly designed with double deep racks of 5 levels. Line Automation to reduce human intervention is very nice and it was pleasing to see so many women working at the factory – women empowerment.

Chief Operating Officer

NextOn Foods Pvt Ltd